Riverina Fresh: Heart of the land

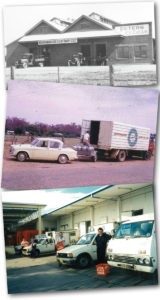

Riverina Fresh has been producing dairy products since 1922

Twenty local farmers are responsible for its award-winning milk and hope to continue their profession for generations to come.

The morning sunrise casts a pink glow over Simone and Neil Jolliffe’s property in Wagga Wagga, New South Wales. It’s a frosty start to the day at 3°C but the 250 Holstein Friesian cows lined up for the morning milking don’t seem to mind. They take their orderly position one behind the other like they’re waiting in line for a footy finals ticket. Like any diehard fan, there’s a bit of argy-bargy to ensure a prime position, but they all get their turn in the herringbone dairy, with the reward of a feed for their efforts.

“If the cows have a full belly, they’re happy,” Neil says. “We feed them as much grass and hay as we can, and they get about eight kilograms of grain each day.”

Neil and Simone are used to the early starts, dirty aprons, and the free-flying faeces. Their farm has been delivering Riverina Fresh milk for the past 19 years.

The Jolliffes’ farm is located in the heart of the Riverina region, an area known for its perfect balance of climate, land profile, and close proximity to Riverina Fresh’s production facility.

“Time is everything. There are lots of little variables that impact the composition of the milk and its overall quality. That’s why Riverina Fresh prioritises a fast turnaround from farm to processing and bottling,” Simone says.

At the factory, Site Manager Kim Williams, a dairy industry veteran and Riverina Fresh employee of six years, oversees the daily manufacturing operations. Tankers from surrounding farms arrive every few hours full of milk cooled to 4°C.

First, the product is homogenised to break up the fat particles for even distribution. It is pasteurised and standardised to consistent fat and protein levels, and then filled into blown bottles for shipment within 24 to 48 hours. Kim says he started in the dairy industry hand-bottling and packing 72 bottles per hour. Now, automated filling equipment helps him produce thousands of bottles of milk in the same timeframe.

All milk is tested for bacteria levels and composition, with the finished product reassessed for taste, textural properties, and functional performance. The MilkcoScanFT120 measures the content of proteins, fats, and lactose in each batch of milk. A phosphotase test measures pasteurisation, and a Mettler Toledo measures the level of pH, an important indicator of impurities, spoilage, and compositional change. For milks like Riverina Fresh’s Blue and Gold brands, a further test on a commercial coffee machine measures the ease of texture and strength and hold time of the foam.

Riverina Fresh CEO Rob Collier says the Australian owned company is committed to supplying premium products that meet the needs of its customers and has been doing so for the past 97 years. It has seen many changes over that time, including the move back to an independently owned and run business and a volatile dairy market, but the one thing it remains proud of is its commitment to farmers.

“We have 20 farmers under the Riverina Fresh umbrella. We’re big enough to be good at what we do and small enough to regularly talk with the individual farmers and keep them informed on the business, market movements, and our outlook. Our farmers are a crucial part of the Riverina Fresh family,” Rob says.

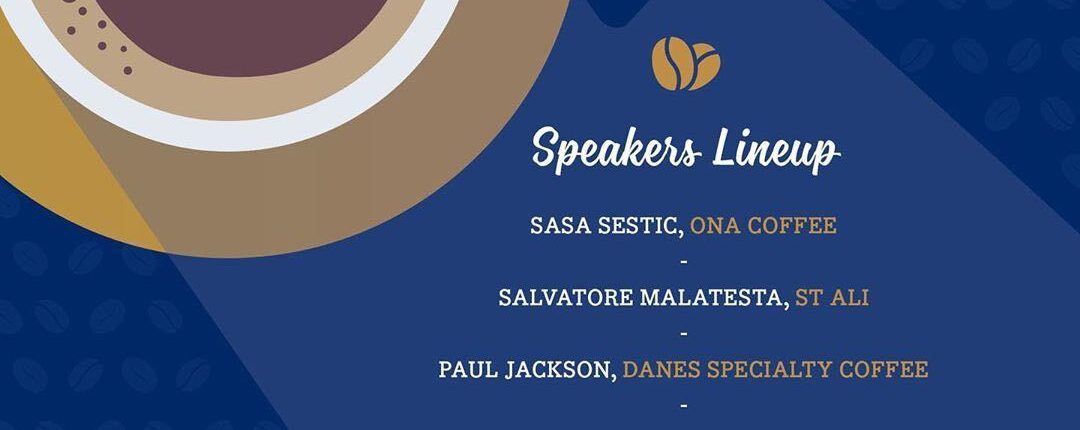

“We all want to be part of something. While some farmers wave their product goodbye at the gate, wondering if it’s turned into milk or milk powder, we have a brand that our farmers can identify with and get close too. In the coffee world, this means we invite our farmers to events like the Melbourne International Coffee Expo (MICE) and have some of the country’s best roasters and baristas come on farm visits to meet our suppliers and learn about dairy farming and milk production first hand.”

Rob attended MICE2013 within a few weeks of taking over Riverina Fresh. He talked to the roasters and learnt pretty quickly that not only was milk very important to them, but that Riverina Fresh was one of the industry’s most revered milk suppliers.

“It was a time when the market was pretty challenging for retail milk, with home brand milk being sold for $1 per litre. I knew that our farmers had a high-quality, consistent product, and that it was well regarded in specialty coffee. I was confident that we could further engage the specialty world,” Rob says.

Initial collaborations took place with premium roasters like Dukes, Danes, and Toby’s Estate who brought Riverina into their circle to better understand the role of milk in specialty coffee. Further collaborations followed, including St Ali, Axil, and Ona Coffee.

When Rob first approached Neil and Simone and the other Riverina Fresh farmers with the idea to supply their dairy produce to the specialty coffee industry, he was largely met with blank faces. Rob convinced them of the strong growth market where quality and consistency were valued, and they haven’t looked back.

“It’s been such a great opportunity for us. We do what the baristas do with coffee – understand all the parameters to what makes a great product, then do our best to measure and control them,” Simone says.

While the specialty coffee industry celebrates quality milk in many of the country’s top-end cafés and coffee competitions around the world, Rob says there’s no doubt Australian dairy farmers are doing it tough.

“The drought and industry-wide milk shortages have seen market pricing increase in recent months, and farm gate prices are at historical highs. However, even with these movements, farmers’ costs of production are at unsustainable levels, primarily due to the input cost of feed and water,” Rob says.

The reality, he adds, is that dairy farmers are shutting down their businesses in droves because they can’t farm sustainably any longer.

“Hundreds of farms have closed across Australia in the past 12 months. Our guys are hanging in there and we’re supporting them and working with them closely, but the key challenge is access to water,” Rob says. “We need an urgent focus from relevant industry bodies and government to unlock workable, cost-effective access to water from our irrigation systems.”

Over at the Burn family’s 1100-acre farm, located 39 kilometres east of Deniliquin, bordering Blighty in New South Wales, the effects of the drought are not so obvious on the surface, but Jo Burn says it’s one of the most noticeable changes in her 17 years of farming.

“Looking out our window, I see green grass, thanks to recent autumn rain, which is key to the success of our business. We make money when we make our own feed, but we are at risk when we rely on a volatile feed market. Currently there’s no-one in our area making close to what they need in feed due to the lack of water. They’re all buying it,” Jo says. “Our current volume of rainfall is not sufficient to support the amount we need on an annual basis to produce close to six million litres of milk per year. What we need is surface and groundwater access.”

Jo and her husband Phil are long-standing suppliers to Riverina Fresh. When Jo made the sea change to Deniliquin to join Phil and his family’s farm in 2002, the area was thriving with dairy farmers because of its close proximity to grain, fodder, and irrigation. These days, Jo says the future of the farm is reliant on the progression of the Murray Darling Basin, one of the largest and most complex river systems in Australia.

“We are in drier times, which is why an irrigation district was set up in our country. But unfortunately there’s lots of politics behind the management of water, inconsistencies, and miscommunication. It’s extremely complex.”

What’s clear, however, is Jo’s line of communication to Rob and the team at Riverina Fresh, and the coffee industry she and Phil have come to love and support.

“When we joined Riverina Fresh as suppliers in 2010, we had a family meeting and decided to put our faith in Rob and the team and his bold idea to focus a key part of our supply to the specialty coffee industry. It’s turned out to be the right decision for our farming future,” Jo says.

Jo is a full time mother to Mitchell, 3, and Daniel, 7, and a passionate farmer. The hours are long, the labour is hard, but she and Phil are happy to continue their farming passion with support from Australian consumers.

“We are proud of our product. It’s a reflection of our hard work, and if it isn’t supported, farms will continue to disappear under financial pressure. We control so much on this side of the farm gate but we’d love to see more people understand the work involved in dairy production,” Jo says.

“We hope people see the value in supporting regional communities and farming families, so that people can continue to enjoy high-quality Australian produced milk and food well into the future.”

This article originally appeared in the October 2019 edition of BeanScene.